More than 15,000 parts required. This is the making of AMR24.

A Formula One car. A fusion of cutting-edge design, technology and engineering.

However, what you see at the track or on TV only tells part of the story surrounding what goes into its production.

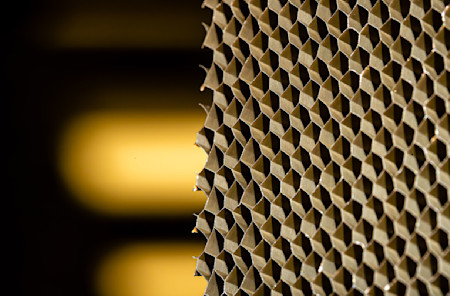

More than 15,000 meticulously designed and produced parts are required to manufacture a Formula One car, and 27,000 pieces are needed over the course of a season.

It's a 3D jigsaw pored over and perfectly put together. In a sport where a millisecond can decide between success or failure, only ultra-precision and hyper-focus will suffice.

As the launch of our new car, the AMR24, draws ever nearer, we're lifting the lid and shedding some light on the parts and tools involved in this painstaking process.

Each piece has a role to play. We're zeroing in on some of the master crafting that goes into getting our F1 car on track, as well as some of the tools that aided production:

I / AM membership

The ultimate fan experience.

Get closer to the team with unparalleled access, behind-the-scenes insights and once-in-a-lifetime experiences, and enjoy exclusive competitions, rewards, offers and more.