With reams of data and insight to come in pre-season testing next week, we're bringing you the lowdown into the six key areas of Formula One's technical revolution.

The development race in Formula One never stops, and today we're bringing you insight into car part production.

With radical new regulations for 2022, Aston Martin Aramco Cognizant Formula One™ Team has been working on the AMR22 for over a year.

With the regulations first slated to come into effect in 2021, the team and its rivals had already begun evaluating their new designs before COVID-19 hit the UK in early 2020.

As the pandemic affected events and workforces the world over, this led to a delay in the introduction of the new regulations and a subsequent pause in development for the teams.

Once F1 returned in 2021, the team balanced development of the AMR21 with work on the AMR22, which is a complete revolution of its predecessor.

AMR22: Tech insights

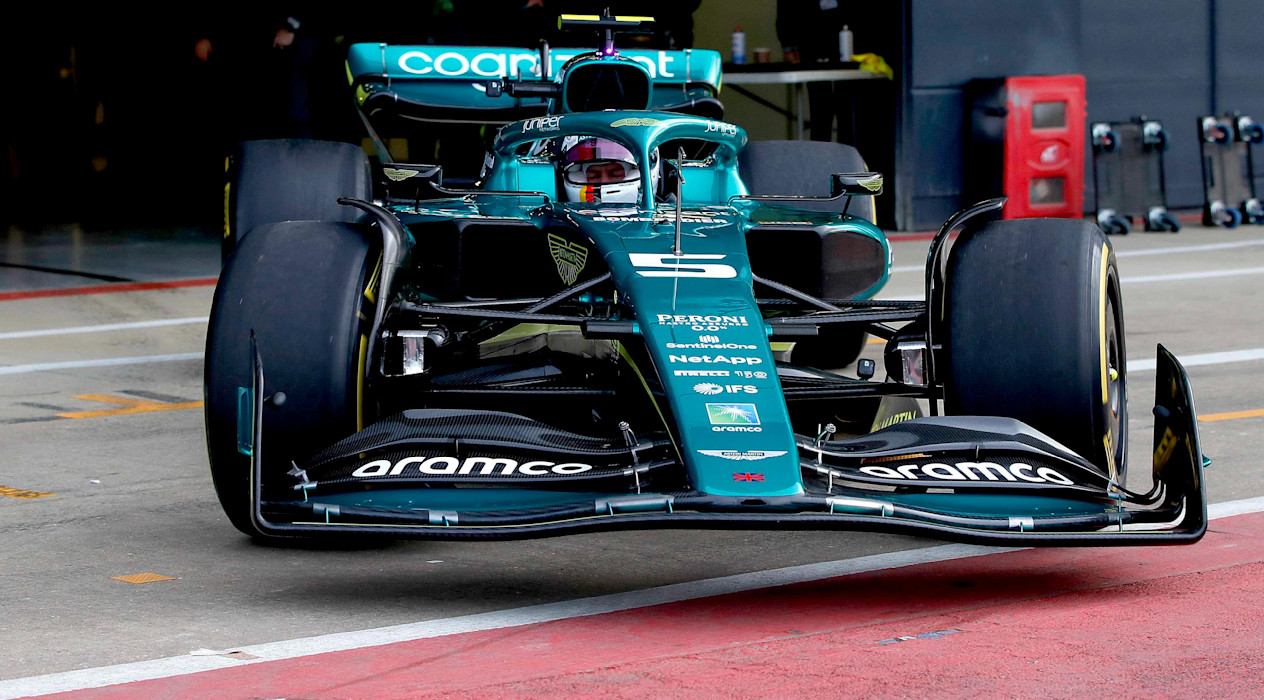

The new era of Formula One has arrived. Designed to produce better racing, and heralding the return of ground effect, the AMR22 represents F1's biggest design revolution in decades.

The team has risen to the challenge, working in unison across design and production to create the thousands of parts that form the earliest spec of the AMR22.

"It's not the easiest thing to do," explains Simon Cayzer, Production Control Manager.

"You're trying to balance two very significant projects, but we can handle that. We've got the capacity and a good team around us to deliver.

"On the production side, we started working with the windtunnel components [for the AMR22] quite early in 2021. The model was in the windtunnel in the early months of the year.

"For the full-size parts, we started manufacturing development parts in June. In early September, we started making real components."

In previous seasons, the production challenge has been aided by a period of technical stability, with significant carryover across cars. But this has not been the case for the 2022 machine.

Sights and sounds of an F1 2022 car

Turn up the volume and immerse yourself in the sights and sounds of a new F1 era, as the Aston Martin Aramco Cognizant Formula One™ Team AMR22 hits the track at Silverstone.

"The AMR21 had a lot of carryover content, but the AMR22 is a revolutionary car," says Simon. "There's probably only around 10% of the car that is a carryover from the 2021 car to 2022.

"That's a relatively small amount, and the regulation changes bring various challenges for us."

The team must also work several races in advance to ensure designs and developments are coming on-stream to the track, with regulation resets always preceding intense and rapid early developments.

"We're trying to push the amount of time for development and design right up to the last minute before we then release them and put them into production," Simon adds.

"We aim to release parts as late as possible to bring the best possible product to the car, first time."

To work to such deadlines, Simon's team of around 35 people, in addition to more than 100 working in wider manufacturing, must work efficiently.

The group spring into action when the design team passes parts into production, overseeing the process through to delivering products to the race team.

Simon's team can have designs released with just hours to make the parts, while more complex parts can require a 12-14 week lead time, meaning there's a constant production schedule to work to.

Access I / AM to get closer to the team.